Supported by National Natural Science Foundation of China (21976085), the research team led by Prof. Guandao Gao, School of Environment, Nanjing University, in collaboration with domestic and oversea scholars, developed a self-cleaning piezoelectric ceramic membrane (PiezoMem) and created an anti-fouling method via using the inherent hydraulic pressure of the membrane separation process to drive PiezoMem to generate a piezoelectric voltage, which realizes self-cleaning of the membrane without the requirement of a further external driving force or cleaning agents. The research results were published in Nature on August 3, 2022, titled "Pulsed hydraulic pressure responsive self-cleaning membrane". Website link: //www.nature.com/articles/s41586-022-04942-4.

Pressure-driven membranes are a widely utilized separation technology in a range of industries such as water purification, bioprocessing, food processing, and chemical production. Despite their numerous advantages such as modular design and minimal footprint, inevitable membrane fouling is the key challenge in most practical applications and can be considered the "Achilles’ heel" of membrane processes. Fouling limits membrane performance by reducing permeate flux or increasing pressure requirements that results in higher energetic operation and maintenance costs.

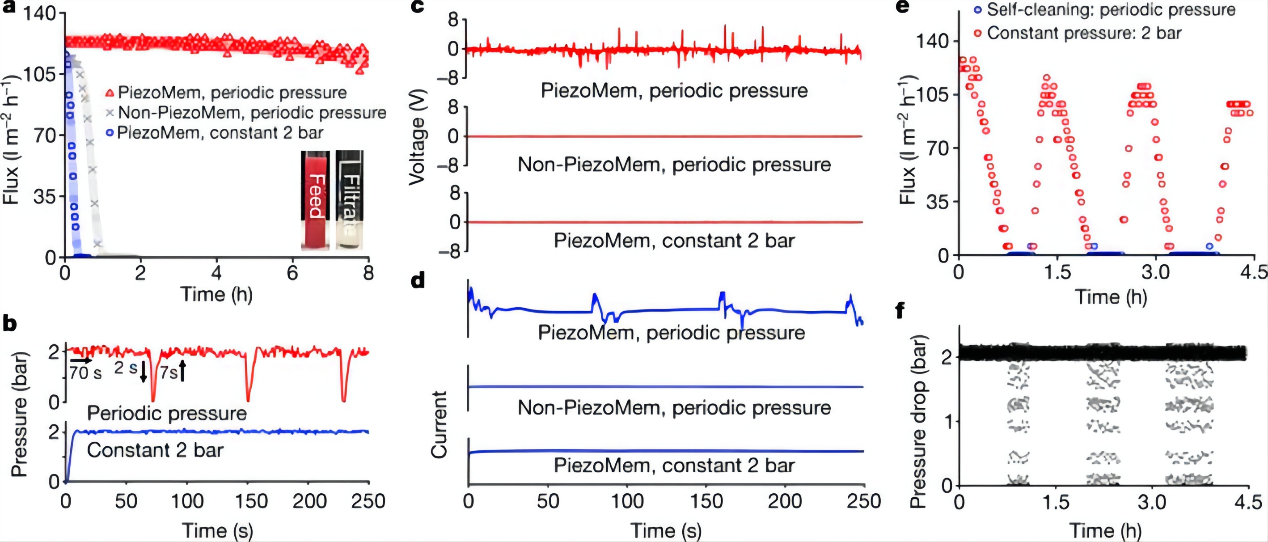

Herein, a hydraulic pressure responsive membrane (PiezoMem) was designed to transform pressure pulses into electroactive responses for in-situ real-time self-cleaning. A transient hydraulic pressure fluctuation result in PiezoMem generation of considerable current pulses and rapid voltage oscillations (peak, +5.0/-3.2 V) capable of foulant degradation and repulsion without need for supplementary chemical cleaning agents, secondary waste disposal, or additional external stimuli equipment. PiezoMem exhibited broad spectrum anti-fouling action towards a range of membrane foulants including organic molecules, oil droplets, proteins, bacteria, and inorganic colloids. Reactive oxygen species production and dielectrophoretic repulsion were elucidated to be the underlying antifouling mechanisms. The hybridization of these two mechanisms was observed to result in a universal antifouling process independent of specific foulant nature. This is advantageous over traditional regulation of membrane surface charge that typically relies on electrostatic repulsive forces that are onlyeffective on colloids of a one particular charge, and is attractive and more adhesive to colloids of the opposite charge. Therefore, the pulsed PiezoMem dielectrophoretic antifouling mechanism discovered here can be used to guide universal antifouling membrane design and application.

In summary, the pressure pulse generated piezopotential enabled an in-situ real-time self-cleaning membrane without need for supplementary chemical cleaning agents, secondary waste disposal, or additional external stimuli equipment. Furthermore, the pressure stimuli responsive antifouling strategy demonstrated here has potential for a vast breadth of applications from household and medical sanitation (ceramic toilet, washing machine, or catheter tubing) and industrial equipment (seagoing vessels, fluid pipelines, or separation membranes) that commonly interact with hydraulic pressure fluctuations. So the strategy to utilize the inherent hydraulic pressure as a driving force to generate in situ electroactivity is a pioneering concept for achieving novel functional materials with potential antifouling, anticorrosion, and/or disinfection properties.

Location:

Location: